Are you trying to understand what average inventory is and how it affects your business? Average inventory is an important financial metric that helps you measure the amount of inventory a business holds at any given time. It takes into account the cost of goods sold, inventory purchases, and other factors, and helps you determine the average amount of inventory that a business is holding. With this information, you can make decisions about how to manage your inventory levels, including when to buy and sell, and when to adjust prices. In this article, we’ll explain what average inventory is, how it’s calculated, and how it can help you make informed decisions about your business.

What Are the Benefits of Knowing Average Inventory?

Knowing the average inventory of a business can be hugely beneficial. Average inventory can help businesses understand their production cycles and inventory levels, which can lead to more efficient use of resources and fewer out of stocks. Having the average inventory information can also help businesses make better decisions about ordering, pricing, and marketing. Knowing the average inventory can also help businesses set more realistic inventory goals and plan for growth. Additionally, having the average inventory information can also help businesses identify areas of inefficiency or overspending. By understanding the average inventory, businesses can better manage their cash flow and make sure they are using their resources wisely.

What Factors Affect Average Inventory?

When it comes to average inventory, there are a few factors that can affect the amount of inventory you have on hand. The size of your business, the type of goods you sell, and the level of customer demand all play a role in determining your average inventory. Additionally, your purchasing and stocking policies, supplier availability, and the seasonality of your industry can all influence the amount of inventory you carry. Being aware of these factors can help you optimize your inventory levels and keep your costs down.

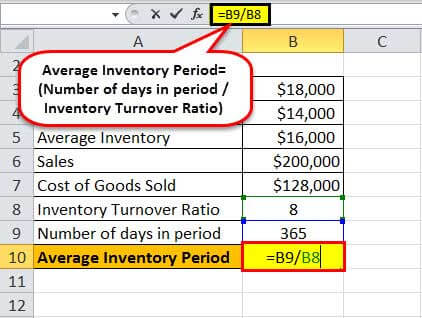

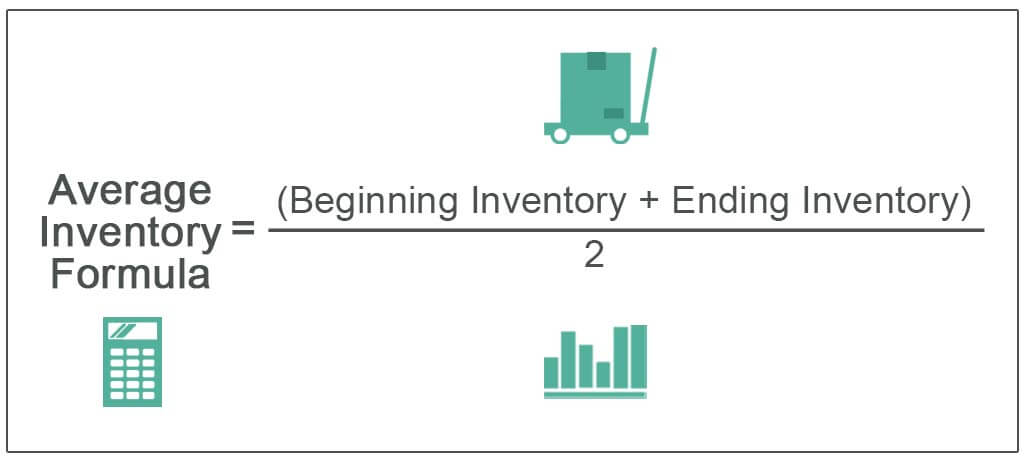

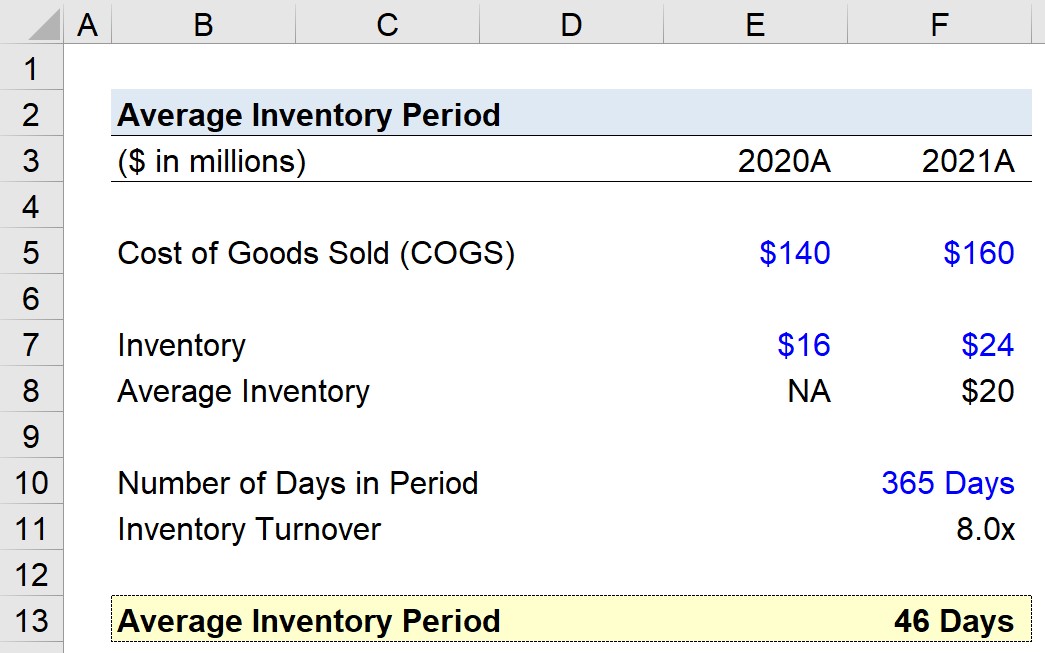

How to Calculate Average Inventory

Calculating average inventory is a great way to ensure that your business is staying on top of its inventory management. It’s important to be able to accurately calculate your average inventory in order to make sure you’re not overstocking or understocking items. The average inventory calculation can be done in a few simple steps. First, you’ll want to total up the value of your inventory at the beginning of the period and then again at the end of the period. This will give you your total inventory cost. Next, you’ll want to add up the total number of items purchased during the same period. Finally, you’ll divide the total inventory cost by the total number of items purchased. This will give you your average inventory cost. This can be used to calculate the cost of goods sold and to help you manage your inventory levels. By using average inventory calculations, you’ll be able to make sure that your business is well-stocked and ready to meet any customer demand.

The Difference Between Average Inventory and Closing Inventory

When talking about inventory, there are two different types that you should know: average inventory and closing inventory. Average inventory is the average of all the inventory that you have over a certain period of time, usually a month or a year. Closing inventory is the amount of inventory that you have at the end of a certain period, such as the end of a month or a year. Knowing the difference between these two types of inventory can help you get a better handle on your finances. Average inventory is a great way to get a snapshot of how much inventory you have over a certain period of time, so you can better plan for the future. Closing inventory is great for getting an accurate count of your inventory at any given time, so you can make sure that you have enough in stock and plan for future orders. Knowing the difference between average inventory and closing inventory can help you make the most of your inventory and keep your business running smoothly.

Tips for Managing and Optimizing Average Inventory Levels

Managing and optimizing average inventory levels is an important part of running a successful business. To make sure your inventory is in the best shape possible, consider taking a few steps to ensure it’s accurate, up-to-date, and efficient. First, consider conducting regular inventory reviews to ensure you have the right amount of stock, in the right places, at the right times. Additionally, make sure to have a system in place to track inventory levels so you can stay on top of what’s being sold and what needs to be reordered. Lastly, consider investing in technology that can help you monitor and manage your inventory in real time and automate processes like stock replenishment and reordering. By following these tips, you can help ensure that your average inventory levels are optimized and your business is running at its best.