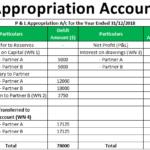

Appropriation is a powerful tool for businesses to strategically allocate financial resources to achieve strategic objectives. It allows companies to plan for their future, by setting aside funds for specific purposes such as research, market development, or capital expenditures. It is an important concept to understand in the world of business, as it can help businesses improve their financial performance, while ensuring they meet their long-term goals. In this article, we’ll explore what appropriation is, the different types of appropriation, and how it can be used to help businesses make better financial decisions.

Exploring the Definition of Appropriation

Appropriation is a term used to refer to the set amount of money that is allocated for specific purposes by a governing body. It is typically a part of the budgeting process in which lawmakers, or other government officials, have the authority to set aside money for specific goals or projects. Appropriation can also be used in a more general sense to refer to something that is taken or used without permission. For example, if someone takes a piece of art and uses it without the artist’s permission, this can be seen as an appropriation. Appropriation is a concept that is used in various ways, both in the public and private sectors. It is an important part of understanding the financial system, and it is important to understand the concept of appropriation when looking at the budgeting process.

Understanding Appropriation and Its Financial Implications

Appropriation is an important concept to understand when it comes to managing your finances. Basically, it’s the process of setting aside money for a specific purpose, like savings or investing. Understanding how appropriation works and its financial implications can help you make better decisions when it comes to budgeting and financial planning. With appropriation, you can plan for the future by saving money for a rainy day or investing in something you believe will be profitable down the line. Appropriation can also be used to pay down debt, or to make a large purchase. Knowing how to properly use appropriation is a key tool in managing your finances and making sure you’re on the right track.

The Difference Between Appropriation and Plagiarism

It’s important to understand the difference between appropriation and plagiarism. Appropriation is the act of taking something from another source and using it to create something new. Plagiarism, on the other hand, is the act of taking someone else’s work and presenting it as your own. Appropriation is a way to show respect and admiration for another artist’s work, while plagiarism is a form of theft. Appropriation can be a great way to express creativity and show appreciation for other people’s work, while plagiarism is a serious offense that can lead to serious legal consequences. So make sure to keep these two concepts separate and don’t forget to give credit where credit is due.

How to Appropriate Ideas While Avoiding Plagiarism

When it comes to coming up with original ideas, it can be hard to know where to draw the line between appropriating other people’s ideas and plagiarism. Appropriation is a great way to get creative and find inspiration, but it’s important to make sure that you’re citing and crediting your sources correctly. When appropriating ideas from other people, make sure to use your own words and give credit to the original creator. To avoid plagiarism, take the time to research whatever you’re writing about and properly cite all of your sources. Additionally, be sure to give credit to any collaborators you work with, as this is an important part of the creative process. With a little bit of effort, you can come up with original content that is truly yours while avoiding plagiarism.

The Benefits of Appropriation in the Creative Industries

Appropriation can be a great thing when it comes to the creative industries. It allows artists to take inspiration from others and create something that is unique and meaningful. With appropriation, artists are able to take bits and pieces of someone else’s work and incorporate it into their own, creating something entirely new. Appropriation gives creativity a chance to run wild, as artists can take the best parts of multiple pieces of work to create a unique and unforgettable experience. It can also be used to add new life to something that may have been forgotten, as it allows the artist to give their own spin on a concept. Appropriation is a great tool for the creative industries, as it allows artists to be truly creative and push the boundaries of what can be done.